-

Admescope 2023 lookback

“Welcome to 2024! We couldn’t wait for 2023 to end,” was […]

-

Overcoming Hurdles in ADME Research for PROTACs

Targeted protein degraders (TPDs), also known as proteolysis targeting chimeras (PROTACs), […]

-

Meet the team: Part 4

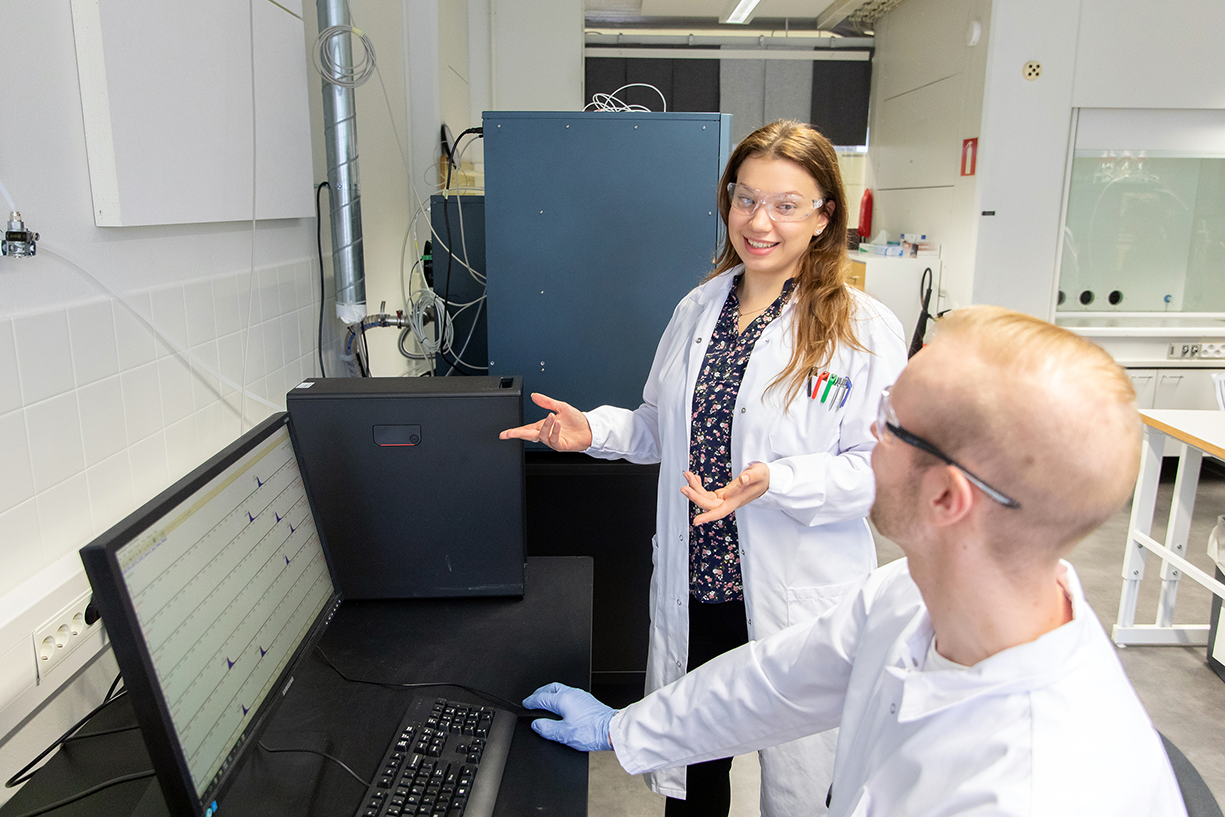

Since the founding of the company over 12 years ago, Admescope […]

-

Exploring Oligonucleotide-Based Therapies: ADME CRO Perspective

In recent decades, the pharmaceutical industry has witnessed a remarkable surge […]

-

Are you close to candidate selection? An IND/IMPD enabling drug developability assessment may help in compound consideration.

Drug discovery and development is a complex and iterative process that […]

-

Greetings from the new CSO

A year and a half after stepping down from the CEO […]

-

Integrated drug discovery and development services – tailored to your needs

Throughout drug discovery and development, there are numerous scientific hoops to […]

-

Admescope 2022 lookback

2022 was full of action, and it marked the most successful […]

-

I have become an Admescopian!

Time goes by fast when having fun – such a cliché, […]

-

Meet the team: Part 3

Admescope welcomes Dr Laszlo Szilagyi, the newest member of the Business […]

-

Meet the team: Part 2

As part of our ‘meet the team’ series, Admescope welcomes Leah […]

-

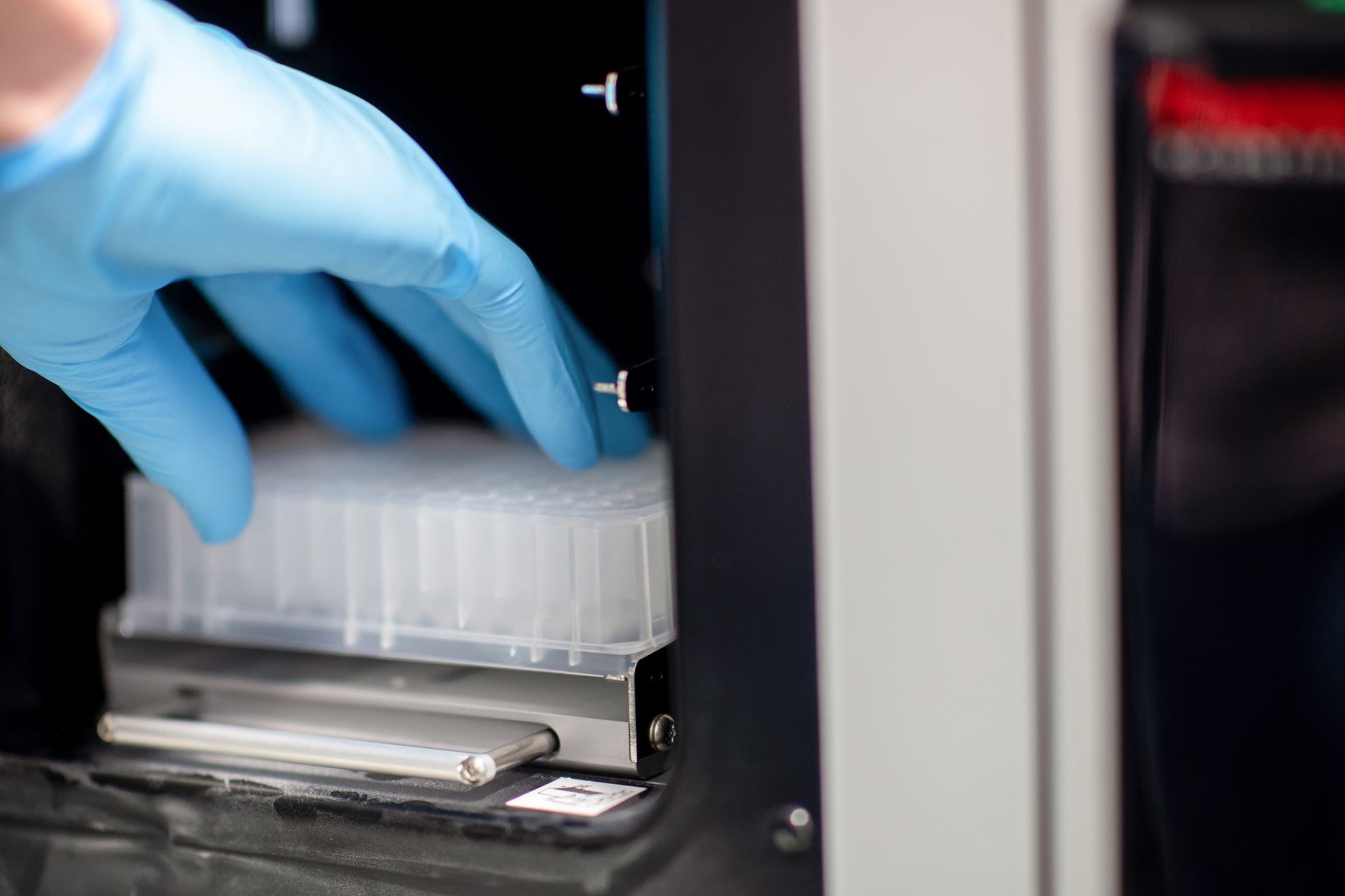

MIST evaluation toolbox – what is in there? Part 4

The overall aim of the safety metabolism studies is to better […]

Feel free to contact us!

Curious to know more about what can we do for you? Get in touch and let’s start a conversation.